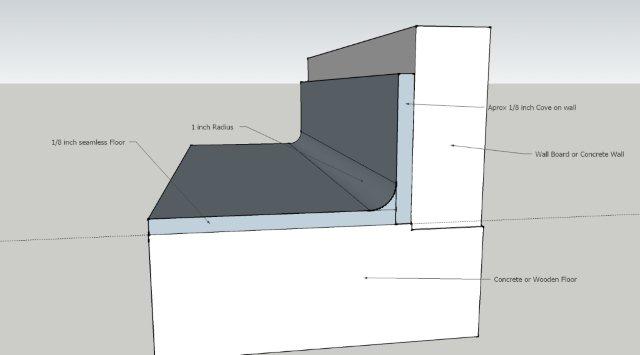

One

of the unique advantages of seamless flooring is the ability to

build an integral cove base. This integral cove allows you to create

a virtual bathtub or shower base out of your seamless floor.

Building this cove was a difficult job until the introduction of

Epoxy.com Product #720 Coving Gel

www.epoxy.com/720.aspx. The coving

gel is mixed with special fillers to create an easy to install custom built

floor to wall base cove.

One

of the unique advantages of seamless flooring is the ability to

build an integral cove base. This integral cove allows you to create

a virtual bathtub or shower base out of your seamless floor.

Building this cove was a difficult job until the introduction of

Epoxy.com Product #720 Coving Gel

www.epoxy.com/720.aspx. The coving

gel is mixed with special fillers to create an easy to install custom built

floor to wall base cove.

Advantages of a Cove Base

- Prevents water from going under the walls

- In chemical containment applications contains the chemicals to the coved

area

- Makes it easy to clean and disinfect the edges of the floor

- Does not allow bacteria or insects to hide under the wall

- Gives the floor an attractive professional seamless look

- Required by government officials in many food and pharmaceutical

applications

Step 1, Surface Preparation

All high quality installations begin with proper surface

preparation. The substrate must be clean, solid and porous. The

substrate must be free of paint, sealers, oil, grease or any other

contaminants that will interfere with the soaking in of the epoxy

primer

www.epoxy.com/surfaceprep.aspx. Be sure the floor and wall in the areas near

the cove are clean. That will help prevent dragging dirt and other contamination

into the cove and make the tape to mask the cove stick better.

Step 2, striking a line

Cove is typically installed at 4 inches high, but specialty applications may be

as little as 2 inches or as much as 6 or 8 inches or even more. Once you know

the height of the cove it must be decided if the top of the cove will follow the

contour of the floor or be level on the top. Most floors look best with a level

top to the cove.

Strike a line with a laser level or a chalk line. Mask with a strong firmly

bonding tape like duct tape. Be sure it is pressed down and securely stuck to

the wall.

Step 3, priming

Make a small batch (1 cup A to 1/2 cup of B) of Product #899 primer. Apply the primer on to the area to

receive cove. This application is typically done with a brush or mini roller. It

is important not to put the primer on too thick or it will run. You just need to

have enough primer to give the surface to receive the cove a wet look.

If you have a very porous substrate and the primer soaks in and doesn't look

wet, a second coat of primer may be required. A typical substrate that will

sometimes need a second is sheetrock. If a second coat if primer is required it

can be put on before the first coat has hardened. Remember never to wait

more than 1 day before recoating any epoxy.

Step 4, mixing the cove material

After the primer gets tacky and before the primer gets tack free (not sticky to

the touch) you will need to install your #720 cove mix. If your primer becomes

hard before you start troweling up you cove you must prime again. Colored quartz

has different coving batch formulations than other seamless flooring types. Be

sure to consult www.epoxy.com/720.aspx,

for more information about cove mixes.

Step 5, troweling up the cove

Using a margin trowel "rough in" the cove mix material onto the wall where the

cove is going. Be careful not to lift the tape creating the top seal in the

process. Smooth the cove to shape using a cove trowel.

After the cove starts to get slight stiff it is time to make a final pass at

smoothing the cove with your coving trowel. Be sure not to wait too long or the

tape will be difficult to impossible to remove. Be sure to keep our trowel clean

so it doesn't drag the epoxy cove material and make it rough again.

A few drops of a dish washing detergent (like Dawn) in warm water make a great

way to clean your trowel and slick up the cove. Use a rag to clean the cove in

the water. Remove the cove trowel from the water and remove the excess water.

Then return to slicking down your cove.

Once the cove is smooth enough, remove the duct tape, carefully. Remove the tape

at an angle pulling the bottom first so the excess coving material on the tape

stays on the tape and does not fall onto the cove. If pieces do fall on the cove

gently remove the pieces and gently smooth out the damage.

Use our margin trowel to smooth the top of the cove where you just removed the

duct tape. Use the warm water and dishwashing detergent to keep your trowel

clean and slick the top of your cove.

Clean the excess material off from the bottom edge of your cove, unless you have

already done this earlier.

Step 6, sealing the cove

After the coving material has hardened overnight, inspect and lightly sand out

any minor imperfections.

Apply appropriate sealers (listed below). When in doubt, contact Epoxy.com

Technical Support. Apply coating/sealer over the cove by brush and/or squeegee.

Be sure that you do brush out or squeegee out any runs. Keep going back and

checking for runs until satisfied that the glaze (top coating / sealer) will not

run.

- Quartz coves are sealed by applying Epoxy.com Product #15

www.epoxy.com/15.aspx.

- Pigmented Epoxy Coatings, use the same material that you are using on the rest

of the floor.

- Chip Flooring.

- Apply Epoxy.com Product #315 Top Coating by brush over the cove mix.

- Then broadcast the cove into the wet material. If you are careful you can push

the chip up into the coating with your hand or a piece of cardboard or similar

material.

Step 7, install your floor

Install your floor in accordance with manufacturer's recommendations.